DIY & Homeowners

Thank you for your interest in using Concrete Coatings, Inc. products on your next project! We have been leading the industry with the most innovative and durable products for more than 20 years.

We are pleased to offer the resources below to help you select the best Concrete Coatings, Inc. products. We have provided the most frequently requested information hope that we've answered your questions.

Concrete Coatings, Inc only sells direct to the concrete industry. If you have questions about products or installation please work directly with your architect or contractor. Need a reference for a Concrete Coatings, Inc affiliated company? Please fill out the form below and we’ll do our best to match you with a resource in your area.

Please understand—as we are suppliers to the concrete industry only we cannot provide training or information directly to consumers.

NEW! SEE ALL YOU CAN DO WITH CONCRETE!

DIY / Homeowner Frequently Asked Questions

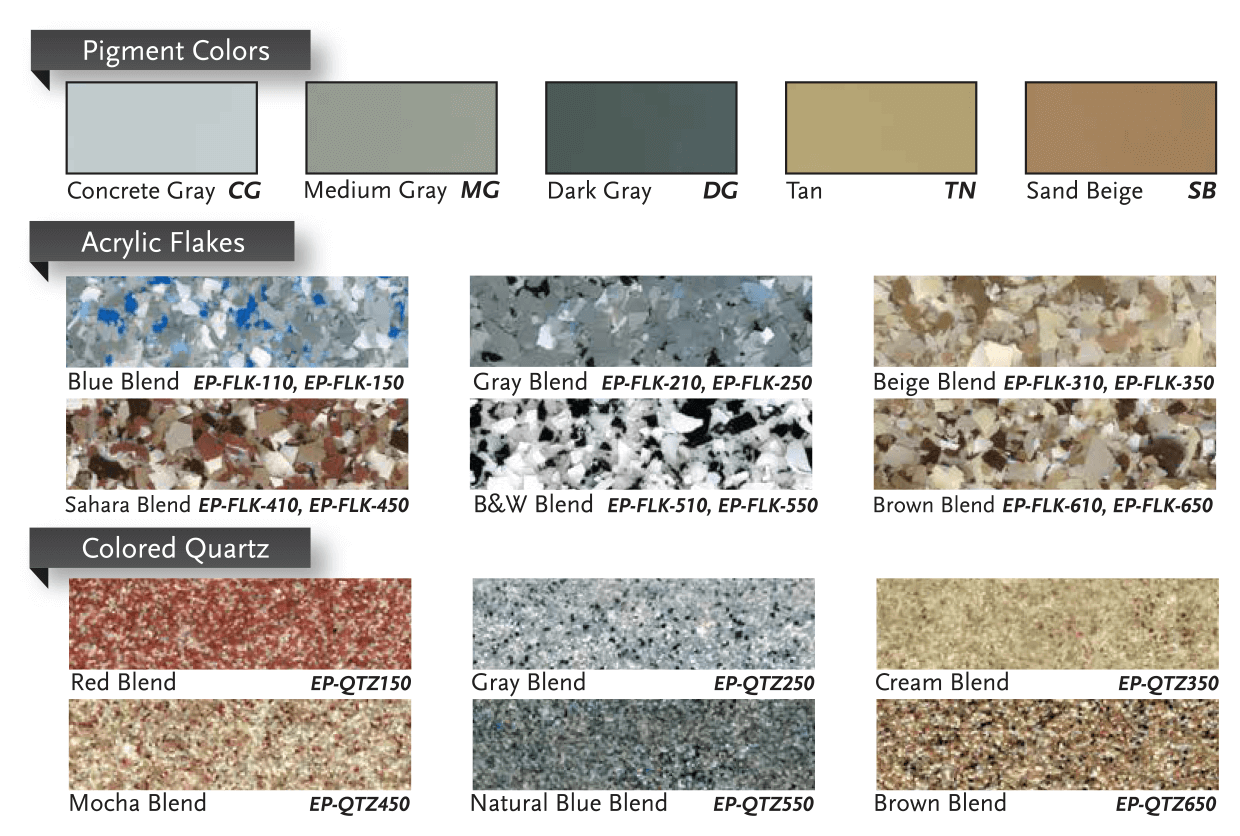

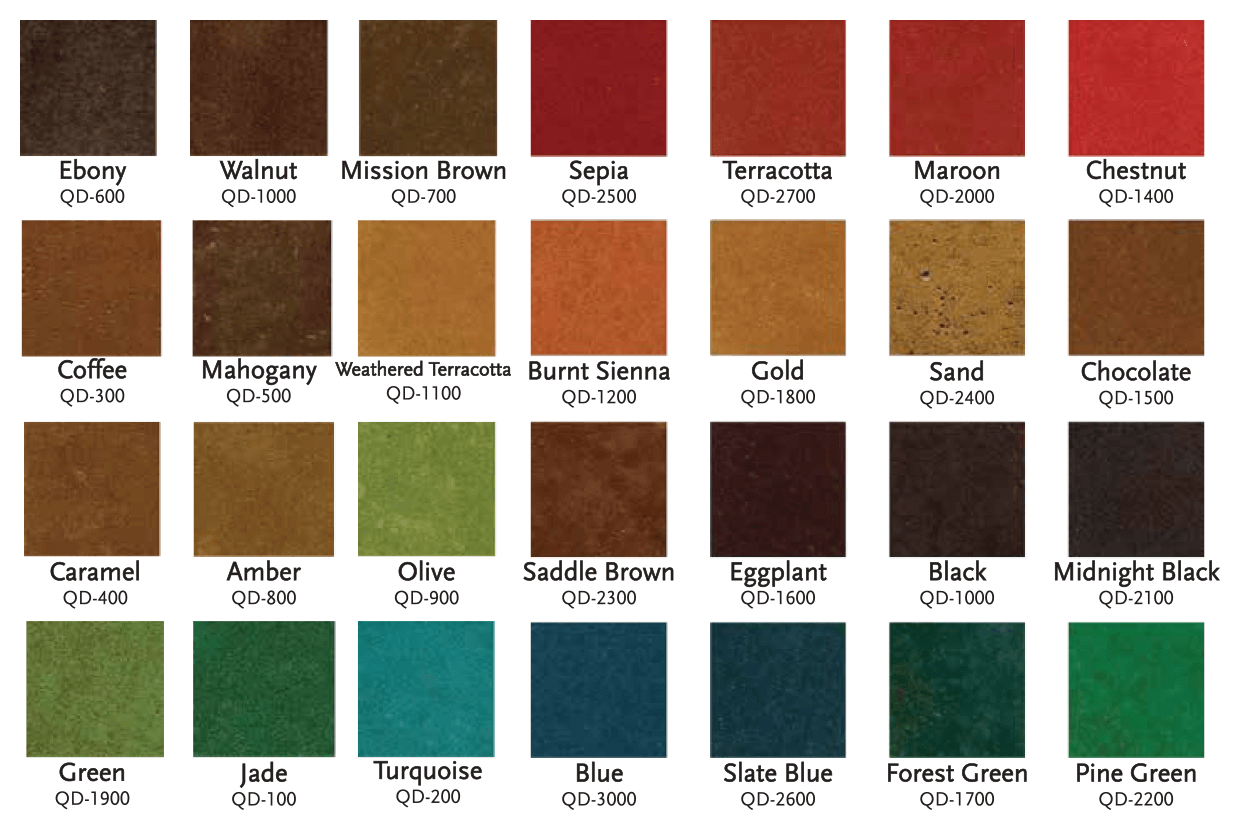

SuperSeal™ 20WB is UV stable and a perfect choice for interior and exterior application. SuperSeal™ 20WB may be applied to many porous surfaces including, stone, brick, manufactured stone, overlays and many types of tile. We recommend you apply sealer to a small section of the substrate to ensure proper adhesion. Use a low pressure sprayer, short nap roller or lamb’s wool applicator to apply Superseal™ 20WB to the substrate. It is crucial not to over apply the material or to allow pooling, as this may lead to undesirable results such as whiting. Reason: Heat. Solvent entrapment usually occurs when excessive heat causes the sealer application to “skin” over the top and the remaining solvent to flash off underneath, causing bubbles. Solution: Applying sealer in the cool of the morning during the hot summer months will prevent most solvent entrapment. However, if this occurs, apply an additional coat of sealer. This causes the sealer to re-emulsify and allow the solvent to escape. Cause: Excessive substrate or external temperatures; or pulling sealer too tight Solution: Cob webbing is most common in the hot summer months due to extremes in temperature. It is best to apply sealer in the cool of the day before the concrete has heated. If cob webbing does occur, apply an additional or heavier coat of sealer and the issue will clear up immediately. Cause: Moisture Entrapment. Moisture entrapment occurs when moisture is left in, or is evaporating out of concrete substrate or if moisture accumulates on a sealer application prior to completing full cure. Solution: Whiting is easily resolved with an application of an acceptable solvent (check your local VOC Regulations to help maintain proper VOC levels). Scrub the affected sealer application vigorously to re-emulsify the sealer and allow for proper ventilation. It may be necessary to repeat this step to fully remove any remaining moisture. Upon curing the whiting should disappear. EZ-Wax™ works well with all of Concrete Coatings, Inc sealers. However, when applying it to a urethane or epoxy the first coat must be applied within 24 hours of the final application to ensure proper adhesion. EZ-Wax™ is completely UV stable. If applied outside consideration must be taken so as not to create a slip hazard. EZ-Wax™ may be applied up to 100 times before stripping is necessary. We recommend the use of a lamb’s wool or terry cloth floor applicator. You may walk on your new epoxy floor 24 hours after the final application. You may begin moving in equipment or utilizing vehicular traffic no sooner than 72 hours. It takes seven days for epoxy to fully cure. All epoxies have a finite window of opportunity to apply additional coats. Any additional material must be applied within 12-24 hours of the last application. Spike shoes are recommended. If this is not possible, the floor must be sanded and deglossed prior to any application of new material. No. However, when applied properly you will achieve a nice even application. We recommend all epoxies are applied with a squeegee in one direction and then back-rolled 90° to eliminate lines and to ensure an even coat. Custom colors may be ordered. There is a 50 gallon minimum and a two week lead time required for processing. Concrete Coatings, Inc., offers five standard pigment colors, six flake blends and six quartz sand blends. The average coverage is 100-200 sq. ft. depending on substrate or desired texture. For example: coverage will be less over flake and quartz than it will be when going over pigmented epoxy. No epoxies are UV stable and all must be used indoors. However, our UV Shield epoxy is extremely UV resistant and is a wonderful top coat for an epoxy floor, acid stain or interior countertop. UV shield may also be pigmented using one of our five standard pigment colors. Concrete Coatings, Inc., recommends 2-3 people for the first thousand square feet and one additional person for each additional thousand square feet. Shot-blasting or grinding is the preferred method of surface preparation for a concrete slab. Your substrate must have a profile to allow for proper adhesion and be free of any sealer, dirt, grime, oil, or residual adhesive. Concrete Coatings, Inc. recommends applying dye upon completion of your 400-grit pass. A second application of dye may be applied after the 800-grit pass to maintain and intensify color. Cleaning is essential to ensure proper adhesion of sealers. We recommend the use of an auto-scrubber or white pad on a buffer to remove excess dye residue. The penetrating agent allows for better penetration and adhesion of the dye, increasing color performance and mottling. The penetrating agent should be added in most instances, especially very tight, power-troweled or polished surfaces. QuickDye™ will yield 200-400 sq. ft. per gallon, depending on various factors including concrete porosity and finish. Absolutely. Doing so will ensure the stain will last and remain on your substrate. If the stain is not sealed it may be tracked throughout the commercial/residential space, wash and wear away etc. If a natural rustic finish is preferred, use a water based or other matte finish sealer. We recommend Superseal™ 20WB or one of our solvent acrylics with the matte agent added. Any plastic sprayer will do. Metal is unacceptable due to chemical reaction and corrosion. Sprayer should be dedicated to acid application. Do not use a sprayer that has contained other chemicals I.e. pesticides. You can, if desired, Cut the stain and apply more than one coat may add to the marbling effect that stains are known and loved for. However, staining at 100% strength cuts labor costs and still creates a coloring effect with highly favorable results. If too much water is added, stain color may not be as brilliant as less acid is reacting with the surface. Reason: If the stain is not fizzing it may signify an unsuccessful chemical reaction. Stain reacts with lime and other latents within concrete substrate. When a reaction does not occur it could signify that the concrete may be too old, washed out and/or chemical residue or oils may be interfering and preventing a proper reaction. If the stain is pooling on top of the substrate, a sealer or other curing agent may still be on the concrete preventing penetration. Solution: Make sure any chemicals on the concrete are removed. If the concrete is old or washed out or you are dealing with a very tight power trowel, it may help to add no more than one cup of muriatic acid to one gallon of Chemical Stain Note: do not add muriatic acid to turquoise; doing so will cause an unfavorable result. Reason: Due to the unpredictability of chemical stains and the multiple variances that can occur, the same acid color can react differently. Solution: It is beyond the ability of Concrete Coatings, Inc. to predict or guarantee an acid stain’s reaction to concrete or other cementitious substrate. The responsibility rests solely with the applicator to perform a test on a small inconspicuous area of the job to get an idea of how the stain will react and look on your specific job site. Notwithstanding these measures, it is impossible to guarantee color depth and chemical reaction throughout the entire substrate. The first application can be applied with a squeegee or trowel at about 200 sq. ft. per bag of RG and SG micro toppings. Coverage with additional coats of smooth grade, usually applied with a trowel, increases due to a smoother surface with less voids etc. The second and subsequent coats are usually applied at 300-600 sq. ft. 1 ½ - 2 gallons of water for rough grade micro topping and 2 ½ gallons of water must be added to each bag of smooth micro topping. Once the water is added it is important to allow time for the polymers to become saturated. Wait 5-10 minutes; then remix and apply. Yes. You must put a base coat down prior to applying a smooth grade finish. Smooth micro-toppings are not designed for repair, spalling and uneven surfaces. We recommend the use of a single coat of RG micro-topping or the use of our G-100 and Duraset™ polymer to prior to applying the smooth grade topping. Yes. All 28 colors in our C Series integral color work well with our overlay. You may also stain or dye the material using our VIVID™ Acid Stain or QuickDye™. Stamp the material when it is firm, not squishy. Unlike concrete, Stamp-Tek™ Stampable Overlay does not require heavy pressure or extreme tamping. Apply only enough even pressure to seat the mat and provide an impression. Allow 36 hours before foot traffic. Concrete Coatings, Inc. recommends the use of a funny or magic trowel. We recommend the use of a gauge rake purchased from your local supply store. The VAE primer is a specialty formulated vinyl acetate emulsion designed to be rolled or sprayed prior to application of the stampable overlay. Once the overlay is placed over the primed surface it re-emulsifies and properly bonds and strengthens the overlay to the concrete.DIY

Referral Request

Need a referral to a contractor or architect in your area that uses Concrete Coatings, Inc. products? Fill out this form and we'll do our best to match you with a resource in your area.