Concrete Coatings Incorporated Spray-Tek™ Acrylic Systems can be applied to any concrete surface, vertical or horizontal.

Category: Spray-Tek™

What surfaces can Spray-Tek™ be applied to?

How soon can Spray-Tek™ be used after application?

For normal foot traffic, excluding high heels, cleats, or spikes: 24 hours *; Vehicle traffic: 3-5 days* (* Under normal temperature and weather conditions)

Can Spray-Tek™ be applied around pools?

MOST DEFINITELY! Concrete Coatings Incorporated Spray-Tek™ Acrylic Systems are the ideal solution for pool and spa areas. They are non-skid, cooler than concrete, and will not stain or be adversely affected by pool chemicals. It also provides a perfect transition from pool to yard, adding that finishing touch like no other product can. Because of its versatility, a stencil can be used to indicate depth markings or areas of safety concern.

Can Spray-Tek™cracks be repaired?

ABSOLUTELY! All cracks are repaired using high strength epoxies prior to applying the skim coat. New tension control joints are then cut, or existing ones cut deeper, to alleviate the tension and allow for the movement that initially created the crack. (Note: Due to the multitude of parameters that can cause cracks, cracks cannot be guaranteed against re-cracking; however, cracks that return are often barely noticeable, and if necessary repairs are virtually undetectable.)

What about heaved sunken or severely damaged concrete?

Heaved (raised) concrete, is generally ground down, or the adjacent section is built up using a variety of materials. Severely damaged sections can be torn out and replaced if necessary. This helps to minimize the cost and time of replacing the entire area.

What about expansion joints? Are they covered up?

Expansion joints and cold or control joints are necessary to prevent cracking of the concrete. Concrete must be allowed to expand and contract with temperature changes. These joints provide a "controlled crack" for this movement. All expansion joints are left in place, we cannot cover them up. We also re-cut all existing joints a little deeper to ensure that when it does move, it moves where we want it to, and not at a different weak spot in the concrete.

How is Spray-Tek™ maintained properly?

Although the Concrete Coatings Incorporated Spray-Tek™ Acrylic System is extremely durable, it is not indestructible. The rule of thumb is this: if it will scratch, chip or damage concrete, chances are it may damage the Concrete Coatings Incorporated Spray-Tek™ Acrylic System surface also. Exercise caution when setting heavy things on it. Take care not to drag heavy items that could scratch it. Periodic washing and sealing is all you should have to do to maintain the surface. Clean oil spills and the like as quickly as possible to keep it looking new.

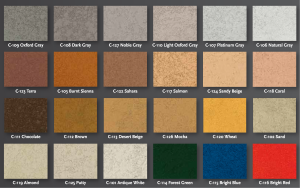

What are Spray-Tek™ color choices?

Will Spray-Tek™ wear or chip off?

Concrete Coatings Incorporated Spray-Tek™ Acrylic System should not show any abnormal wear provided the acrylic sealer is replenished as wear occurs. We estimate this to occur no sooner than every two to three years under normal conditions. As long as the sealer is in place, this protective coating should absorb any wear. Any scuff marks, etc. generally disappear with a fresh application of sealer.

How does it stand up against oils, stains, salts and discoloration?

The protective properties of the sealer coat leave a non-porous finish. The majority of stains due to oil and grease wash off with mild detergent. Salt, deicers, etc. have no effect on it. In addition, because of its unique UV (ultraviolet) additive, it will not discolor due to exposure to sunlight, even in the harshest of conditions. It should be noted, however, that periodic cleaning will help maintain its beauty for many years to come. Cleaning can be performed with a mild detergent such as Concrete Coatings, Inc. EZ Clean. In fact, these protective properties must be maintained through biennial cleaning and sealing.