Shot-blasting or grinding is the preferred method of surface preparation for a concrete slab. Your substrate must have a profile to allow for proper adhesion and be free of any sealer, dirt, grime, oil, or residual adhesive.

- Resinous Flooring

- Shield 50™

Shield 50™

Concrete Coatings, Inc. Shield™ 50 epoxy is a 100% Solids and 100% cross-linked product that can be applied to almost any surface: concrete, wood, tile, stone, etc. It can be used as a primer under a polyurethane application or UV Shield™ topcoat. This product can also be pigmented and used as a primer or topcoat. Unlike most other 100% solids epoxies, Shield 50™ contains no fillers or carriers and its cross-linking provides maximum durability, wearability, adhesion and increased UV resistance. UV Shield™ may be used as a topcoat for greater UV resistance.

- No VOCs - 100% Solids

- 100% Cross-linking

- Low Odor

- Excellent Strength Properties

- Excellent Impact Resistant

- DOT Non-Corrosive

Mix ratio is 2:1 A:B

Technical Information & Downloads:

Packaging: 1, 3, 5 and 15-gallon kits. Drums on request.

Coverage: Average 150 square feet per gallon.

Concrete Coatings, Inc., recommends 2-3 people for the first thousand square feet and one additional person for each additional thousand square feet.

All flooring epoxies are 2:1 A:B

No epoxies are UV stable and all must be used indoors. However, our UV Shield epoxy is extremely UV resistant and is a wonderful top coat for an epoxy floor, acid stain or interior countertop. UV shield may also be pigmented using one of our five standard pigment colors.

The average coverage is 100-200 sq. ft. depending on substrate or desired texture. For example: coverage will be less over flake and quartz than it will be when going over pigmented epoxy.

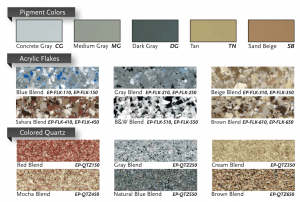

Concrete Coatings, Inc., offers five standard pigment colors, six flake blends and six quartz sand blends.

Custom colors may be ordered. There is a 50 gallon minimum and a two week lead time required for processing.

We recommend all epoxies are applied with a squeegee in one direction and then back-rolled 90° to eliminate lines and to ensure an even coat.

No. However, when applied properly you will achieve a nice even application.

All epoxies have a finite window of opportunity to apply additional coats. Any additional material must be applied within 12-24 hours of the last application. Spike shoes are recommended. If this is not possible, the floor must be sanded and deglossed prior to any application of new material.

All broadcasting should be done within 45 minutes.